Modernization of Gas Purification by JSC Krascvetmet

Krascvetmet is one of the first metallurgic companies of Russia that implemented and certified a system of ecological management that corresponds to international requirements and the requirements of the Russian laws concerning the protection of the environment. All technological processes of the factory are developed to have a minimum impact on the environment.

This job was the first step of a large-scale task to modernize the gas purification of JSC Krascvetmet. The factory problems of gas purification and wastewater treatment are solved by a separate business unit – the “Wastewater Treatment, Gas Purification and Gas Extraction Department of the Refinery Production.” The goal of this job was to conduct a technological and a financial audit of the department and to create propositions for its modernization.

Within the framework of this job, the following tasks were completed:

- Analysis of the department’s expenses (financial).

- Section #1. Wastewater treatment:

- An audit of the existing technological system was conducted;

- An estimate of the capital expenses to construct a new / modernize an existing wastewater treatment block was calculated;

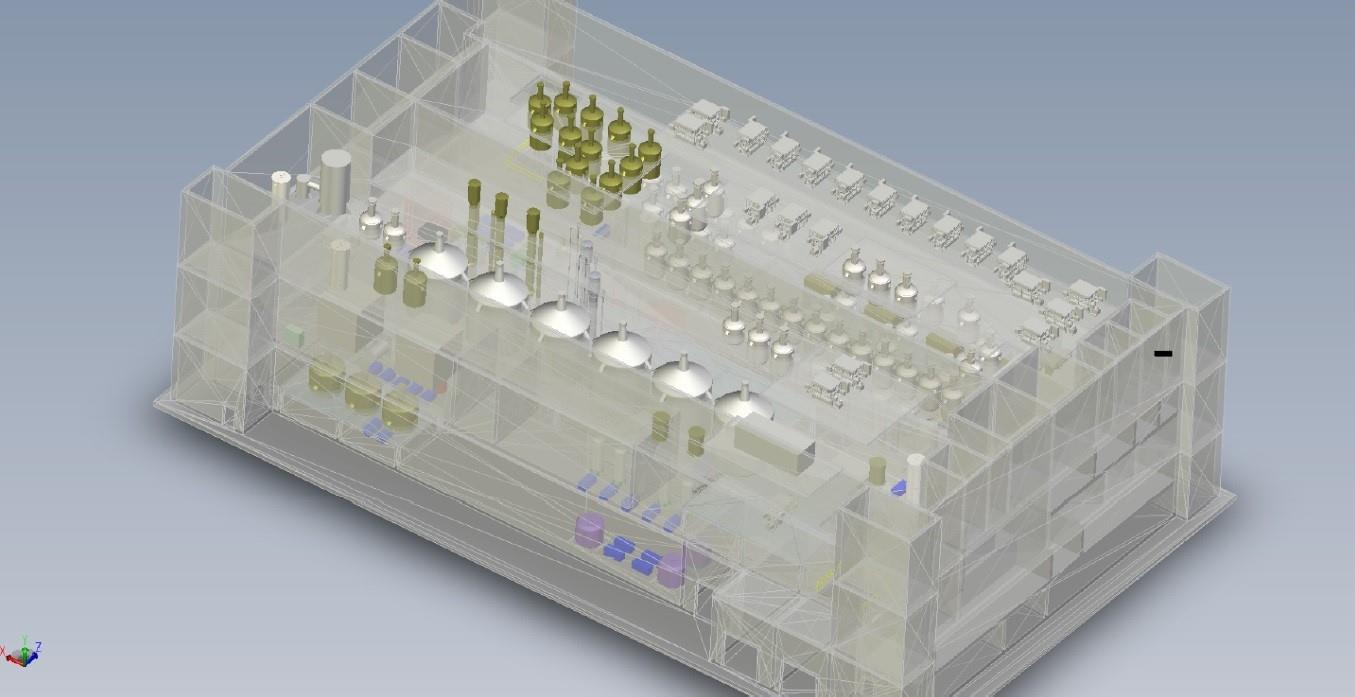

- A 3D model of placing the equipment in a separate building was created;

- A 3D model of placing the equipment in the existing building was created;

- An estimate of the capital expenses to implement the proposed apparatus schematics (2 versions) was calculated;

- Balance calculations were conducted. The salt background of solutions was calculated.

- Section #2. Gas purification and extraction:

- An audit of the existing gas extraction system was conducted;

- A model of the gas flows movement through the current system of gas pipes and cleaning was created;

- An audit of the existing gas extraction system was conducted. Balance calculations were performed; the distribution of harmful elements was calculated as well;

- The conceptual design of gas extraction and purification in a new refinery was developed;

- The calculations of the different options to shift to a medium source of expulsion (through disseminating and sanitary protection zone borders) were made;

- Section #3. An evaluation of possible