Basic Engineering of the Modernization of the Refinery of JSC Krascvetmet

Throughout nine months, we completed work on a complex audit of the technological processes of the refining production of JSC Krascvetmet. Peculiarities associated with modern production were uncovered, connected with the logistics of moving raw materials, the schedules of work completion and the effectiveness of technological and apparatus solutions.

As a result of the work, documentation was developed that allowed for the decision to begin realizing the modernization project of JSC Krascvetmet. The documentation included:

- The feasibility study of the project;

- The design assignment;

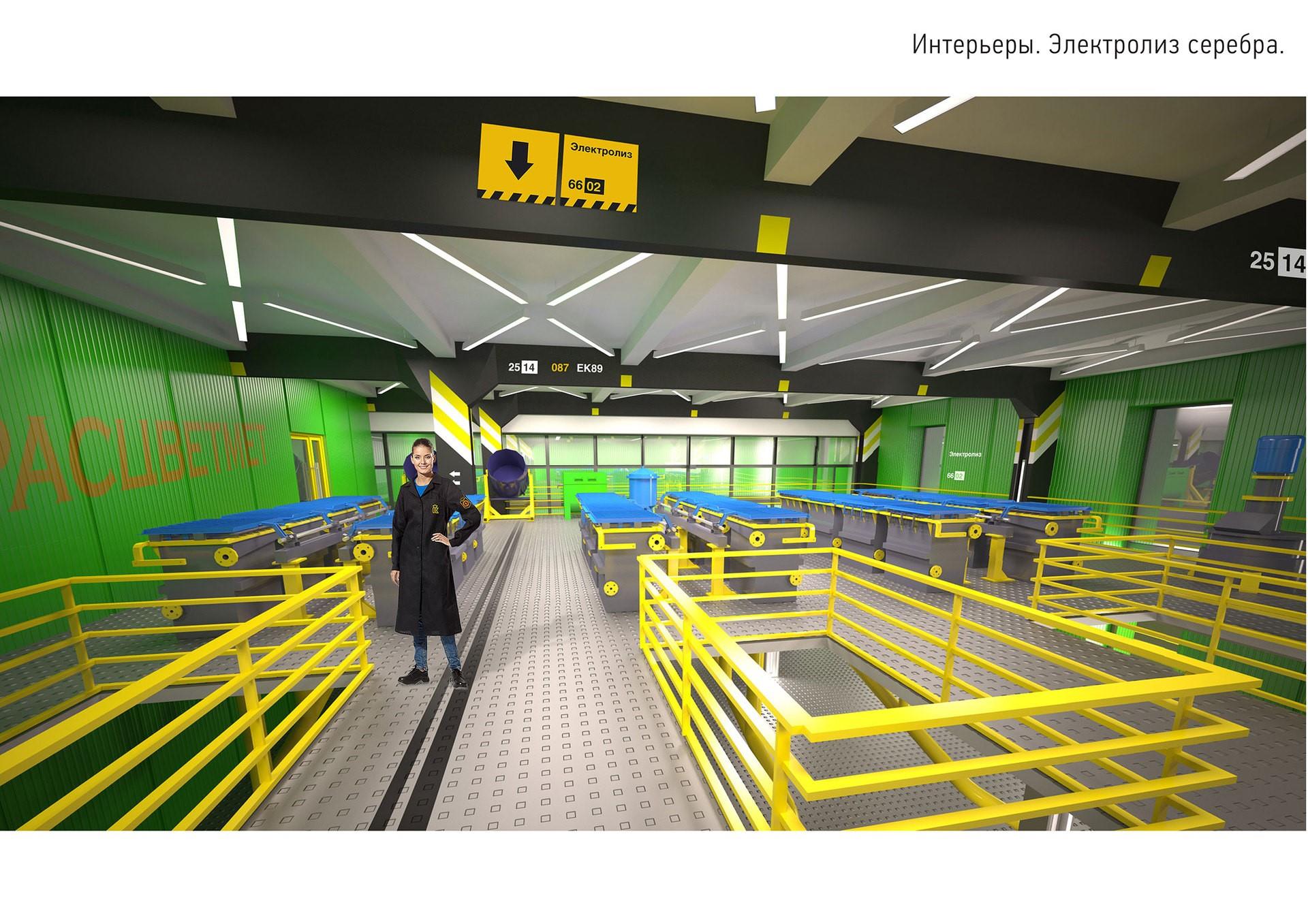

- The architectural concept;

- The 3D model of the refinery production as a whole and each part in particular;

- The plan of the project’s realization, including the project management regulations and the schedule of the project;

- The overall technological schematics.

As a result of such meticulous work on the technical specifications for design, significant improvements were made to the technical – economic indicators of the project. The time for technological processes was minimized due to the realization of the following principles:

- Unification of the areas for accepting raw materials and shipping finished goods;

- Realization of the cascade principle – moving of the raw materials from up to down;

- Optimization of the logistics and the reduction in time for moving the raw materials, the finished goods, and the manufacturing goods within a zone and between zones;

- Unification of zones with a similar functional designation;

- Unification of areas for preparing and distributing reagents.

This project is being currently implemented. Our company is playing the role of an EPCM contractor in the realization of this given project.