Technical audit of the production site Schelkovo Secondary Precious Metals Plant

On September 25, 2019, the technical audit of JSC Schelkovo Secondary Precious Metals Plant (zavodvdm.ru) was complete

The plant is a large specialized refining enterprise for the processing of both mineral and secondary raw materials containing precious metals: gold, silver, platinum, palladium. The raw materials basket includes: raw gold, Dore alloys, concentrates and cement, jewelry and electronic scrap and other materials. The company produces silver-containing composite powders for industrial use, gold and silver bullion and granules, silver salts. Since April 2017, the main partner of JSC Schelkovo Secondary Precious Metals Plant has been Yuzhuralzoloto Group of Companies JSC.

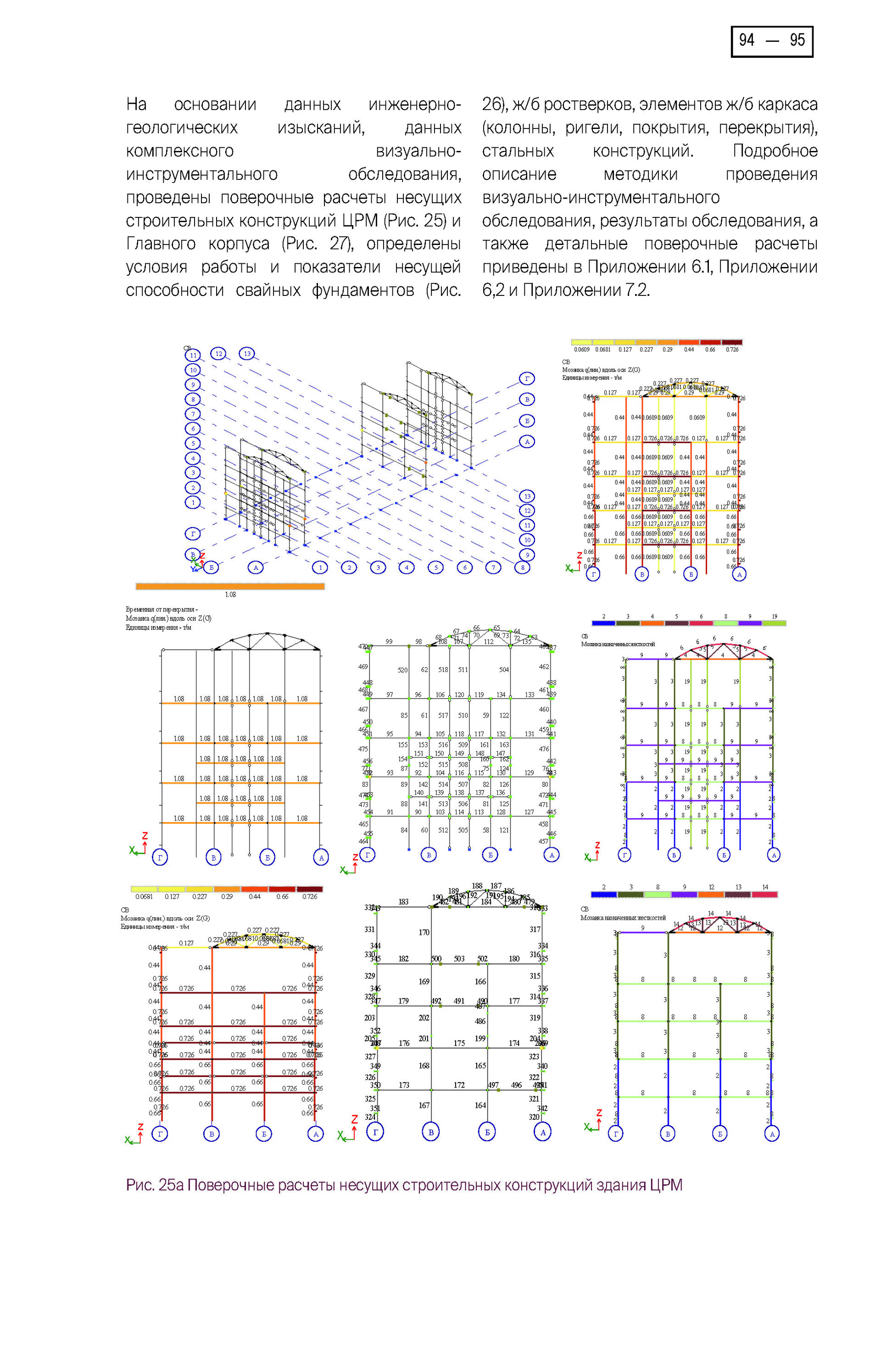

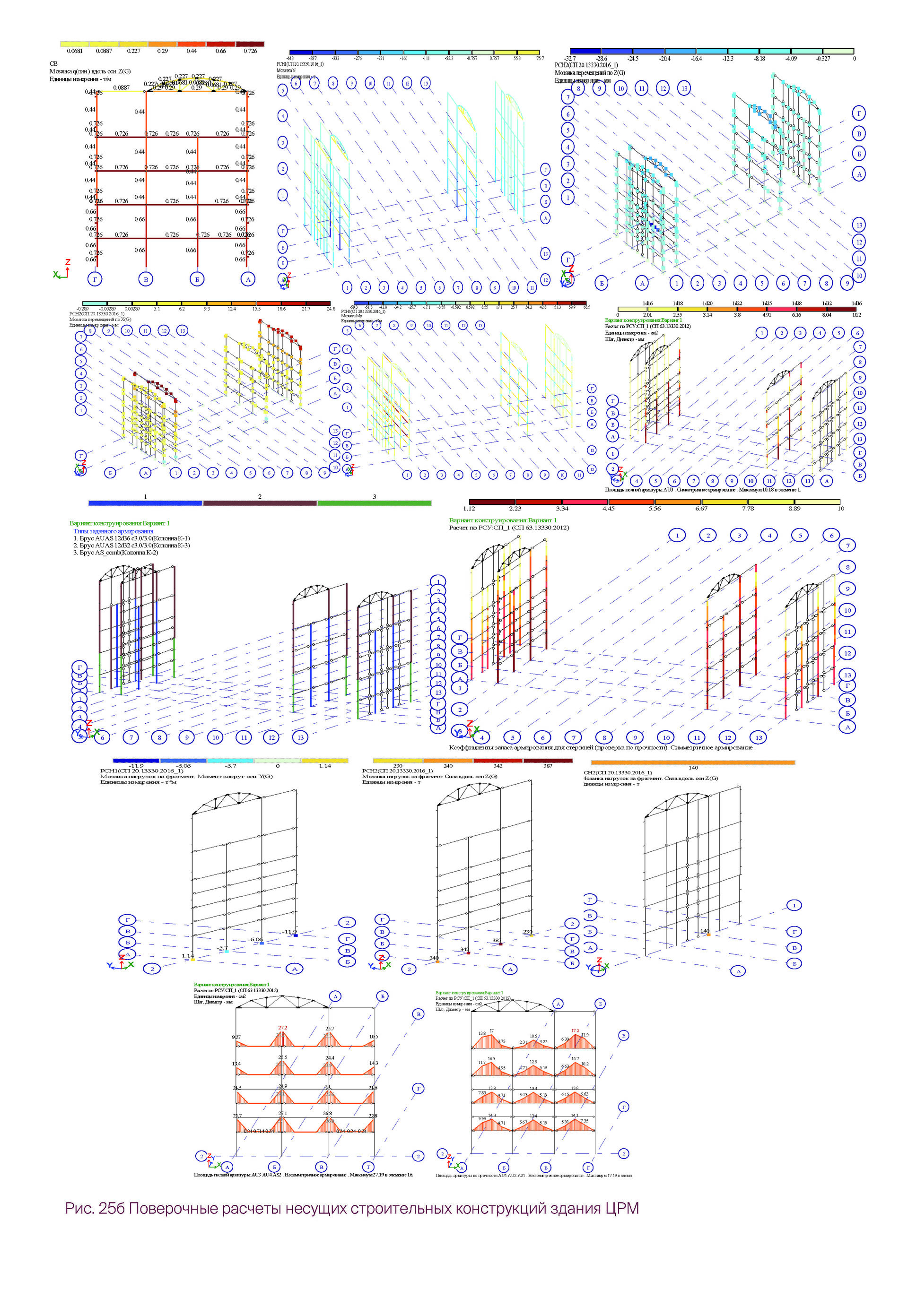

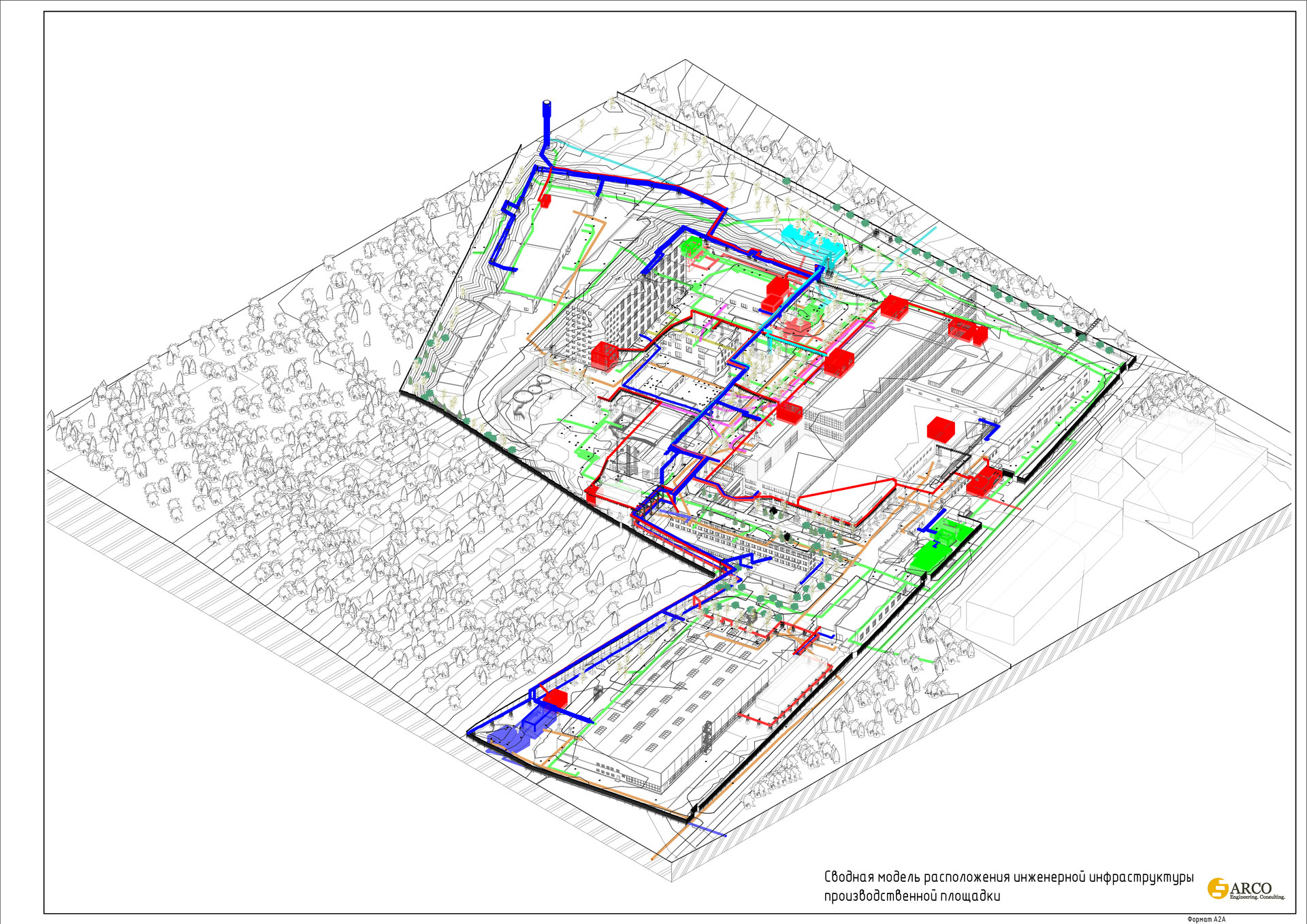

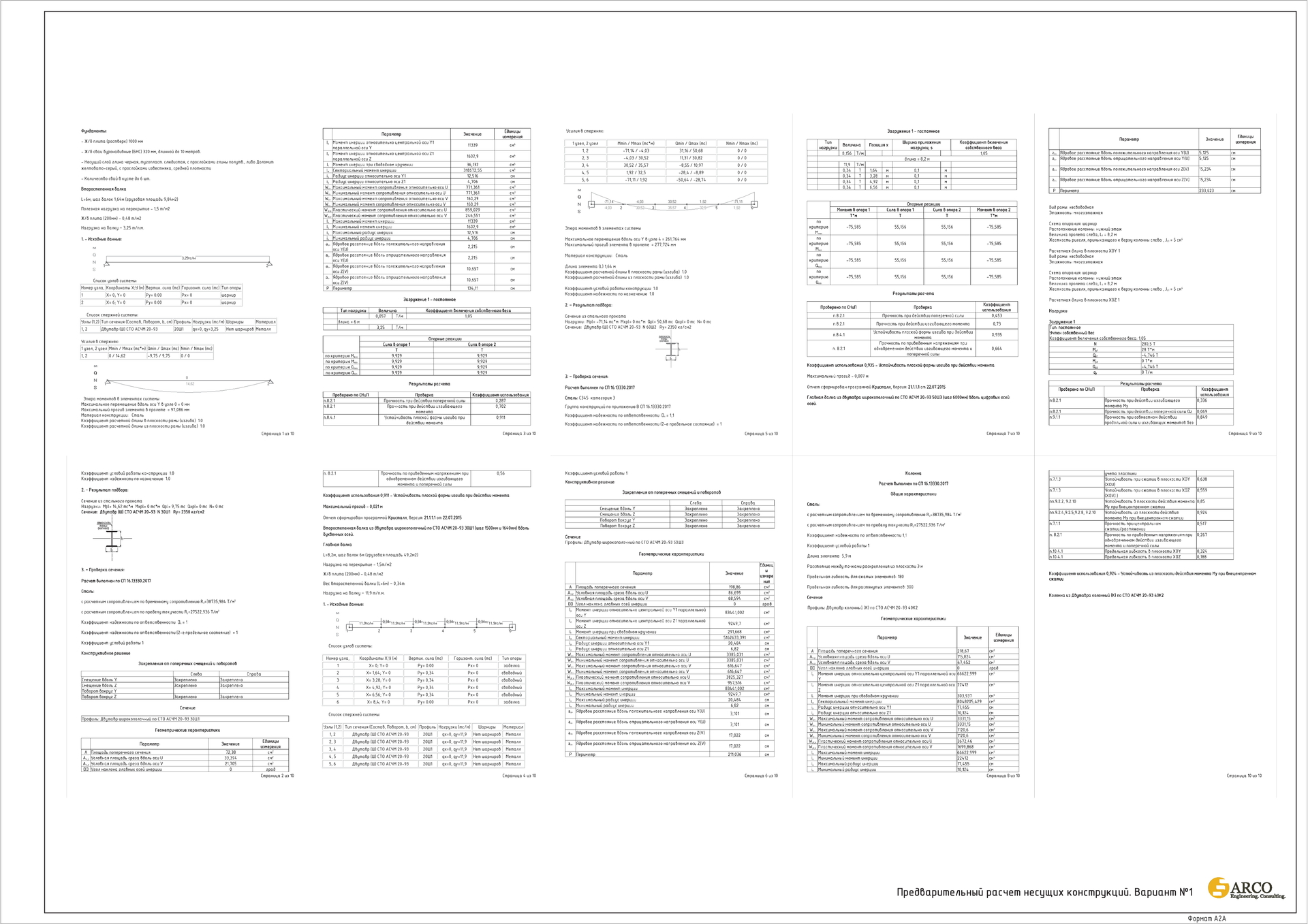

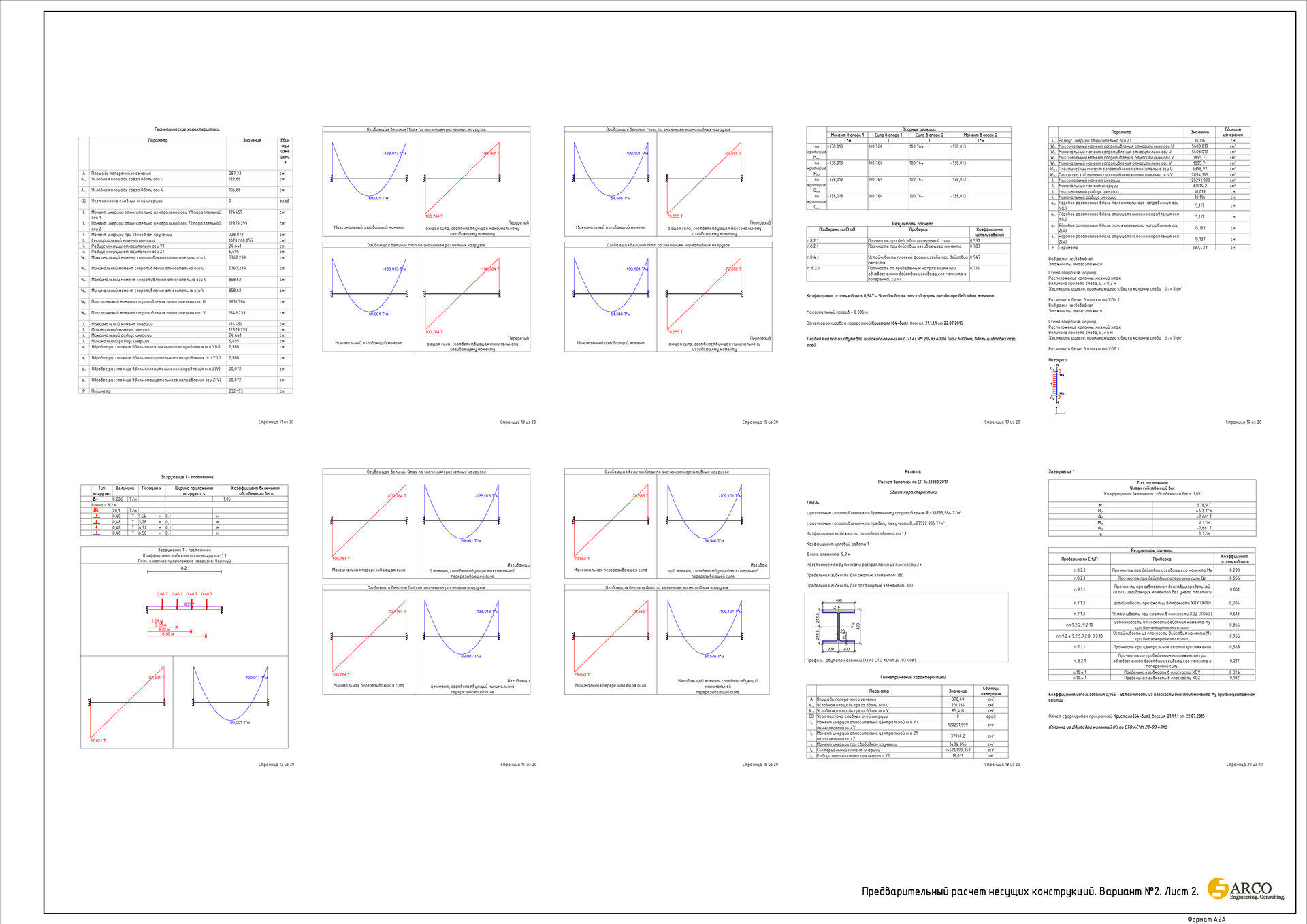

The specialists of ARCO LLC performed the collection of initial data and a comprehensive analysis of the available design and technical documentation, formed objective and reliable data on the actual condition of industrial buildings, structures, utility networks, and basic technological equipment.

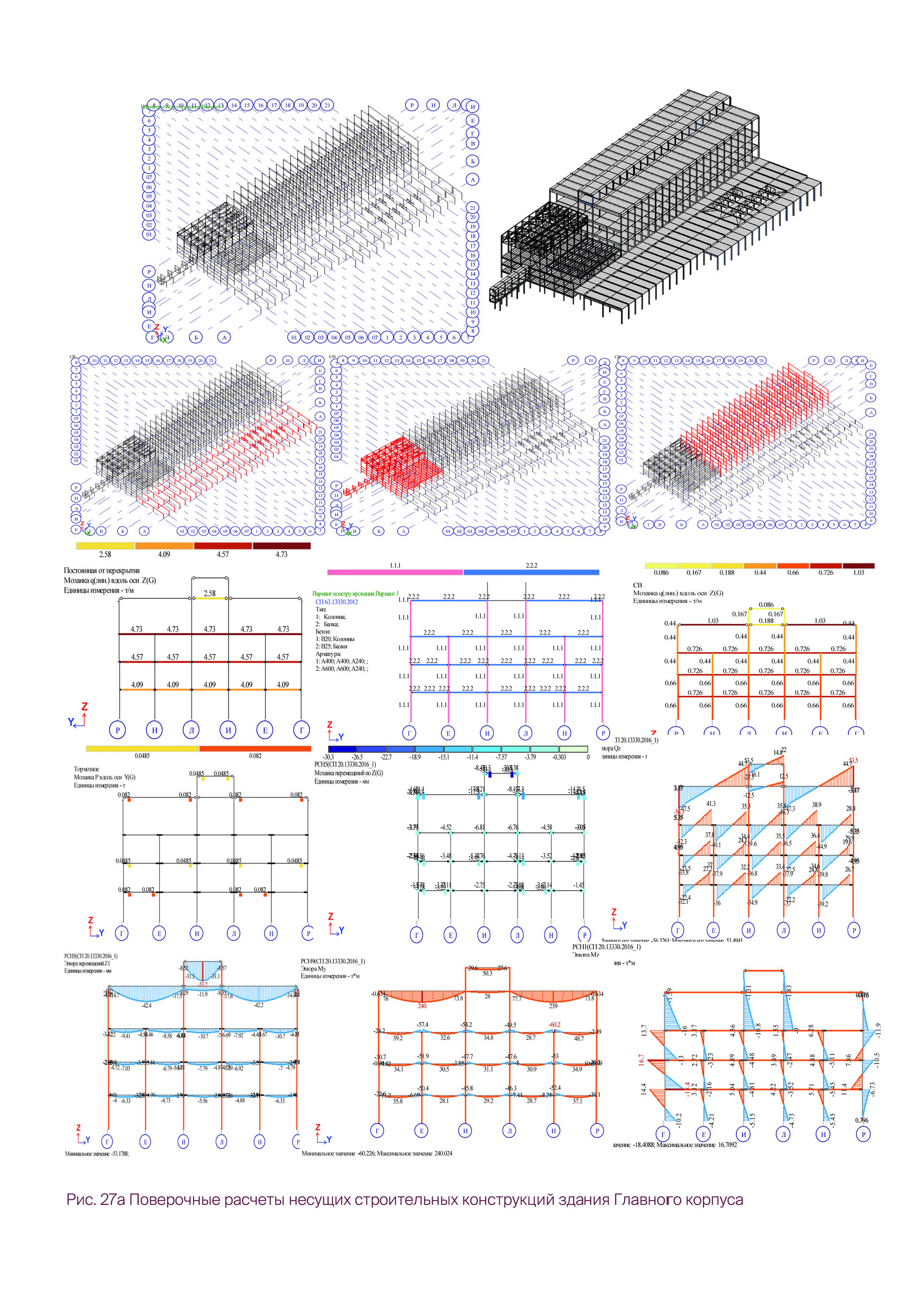

Work was carried out and reports were prepared on geotechnical surveys and the results of full-scale visual and instrumental studies and verification calculations on the buildings of the Rare Metals Shop and the Main Building, on-site engineering systems and equipment.

Based on the results of the work, proposals and events were prepared for the customer.

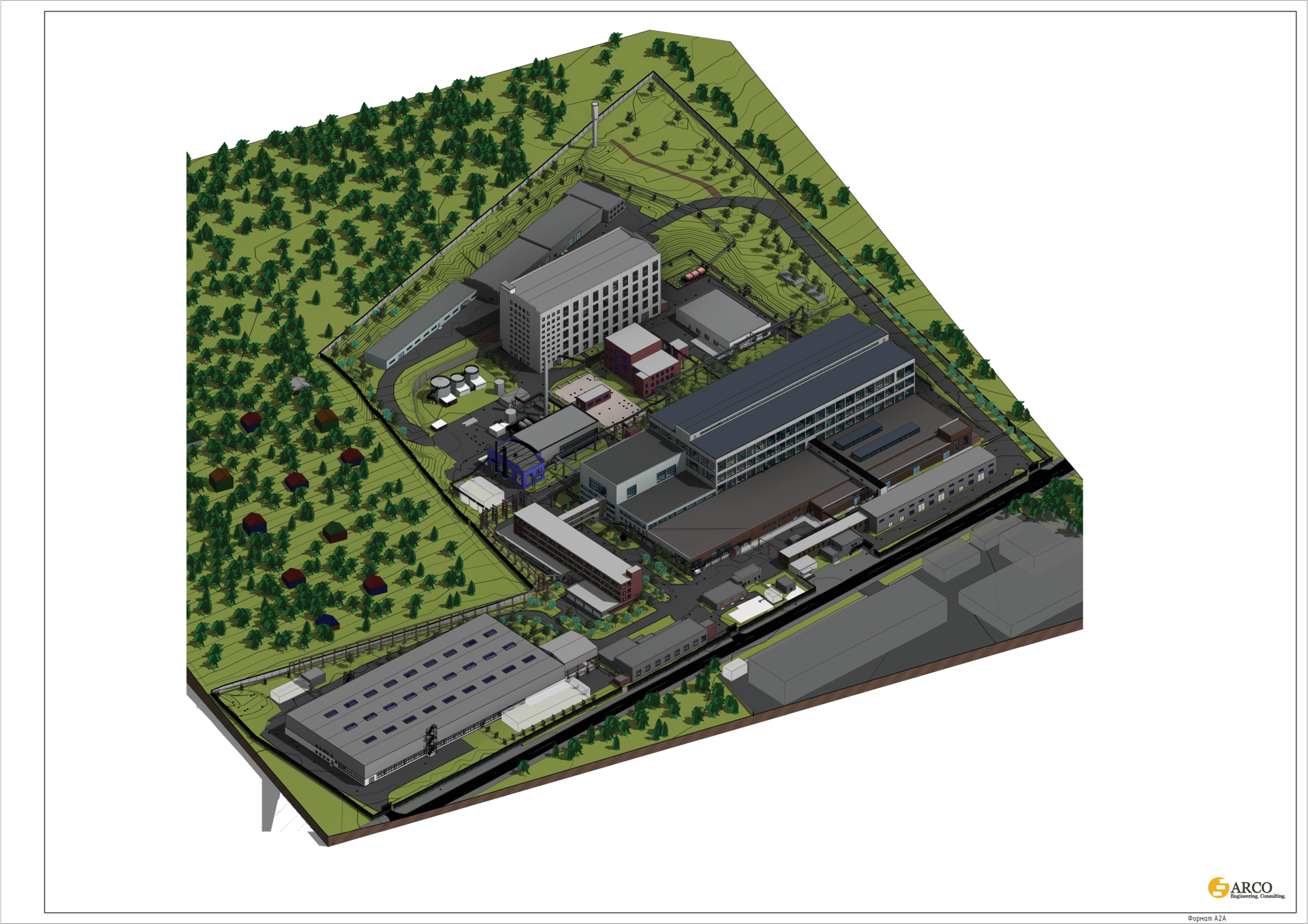

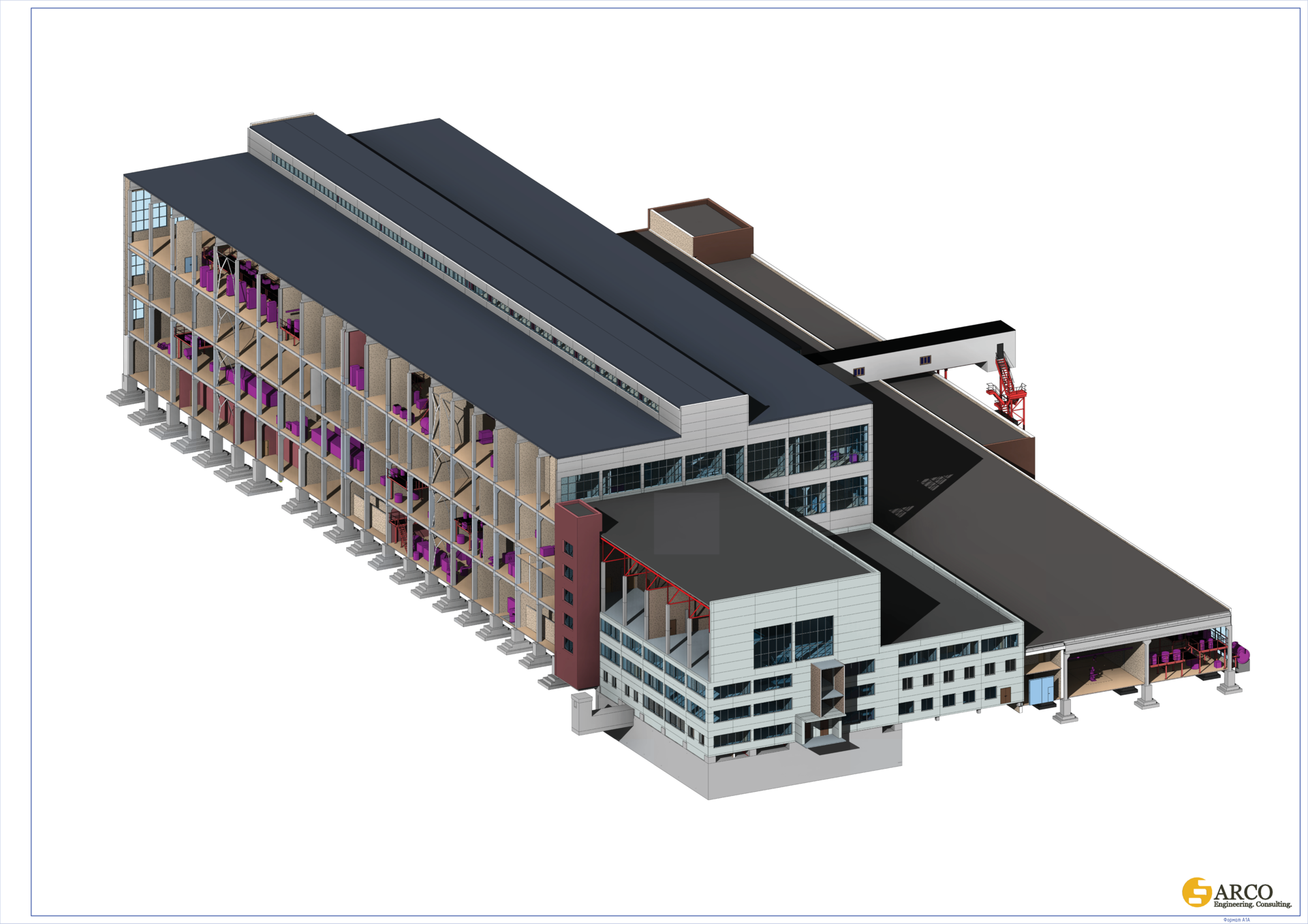

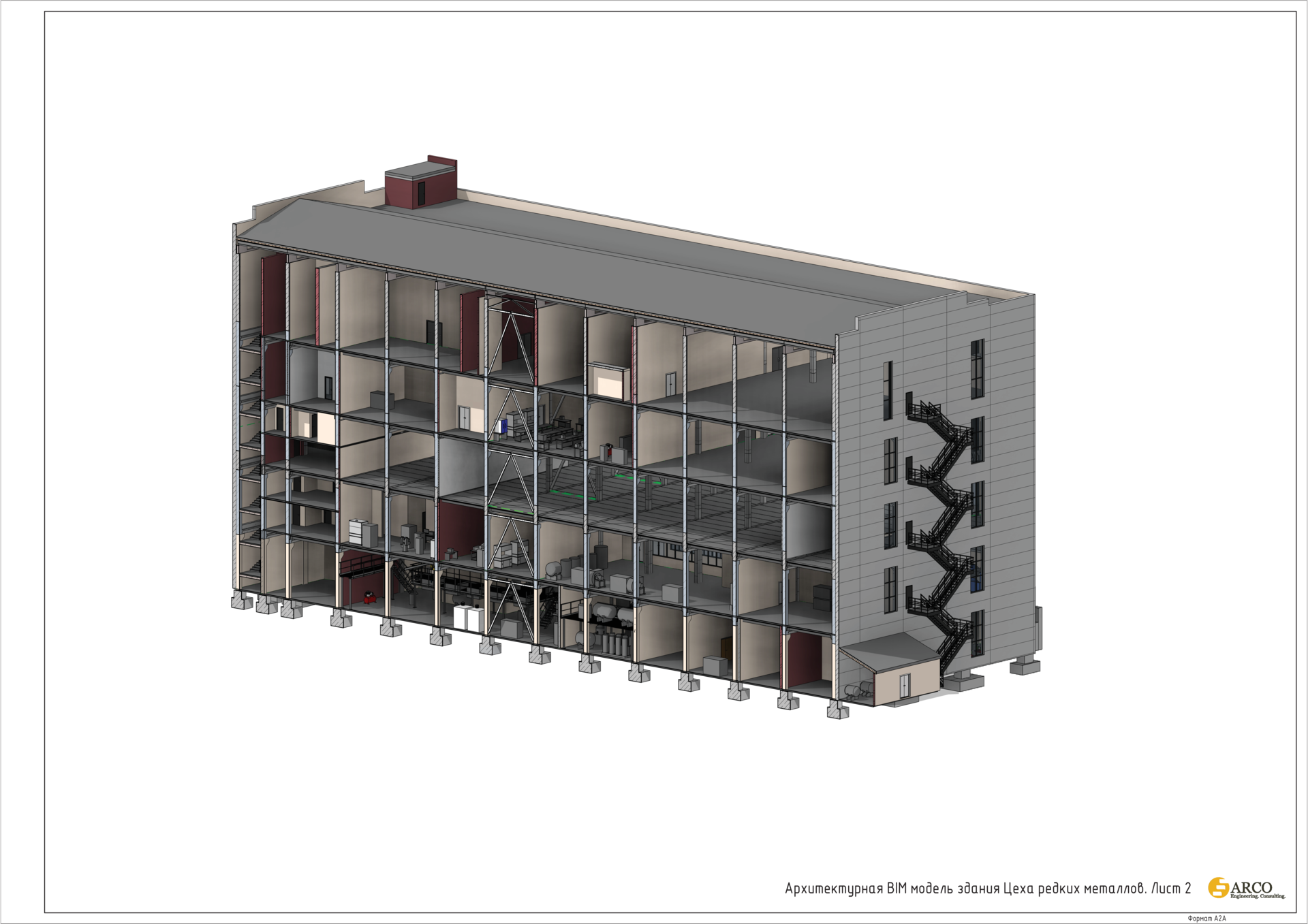

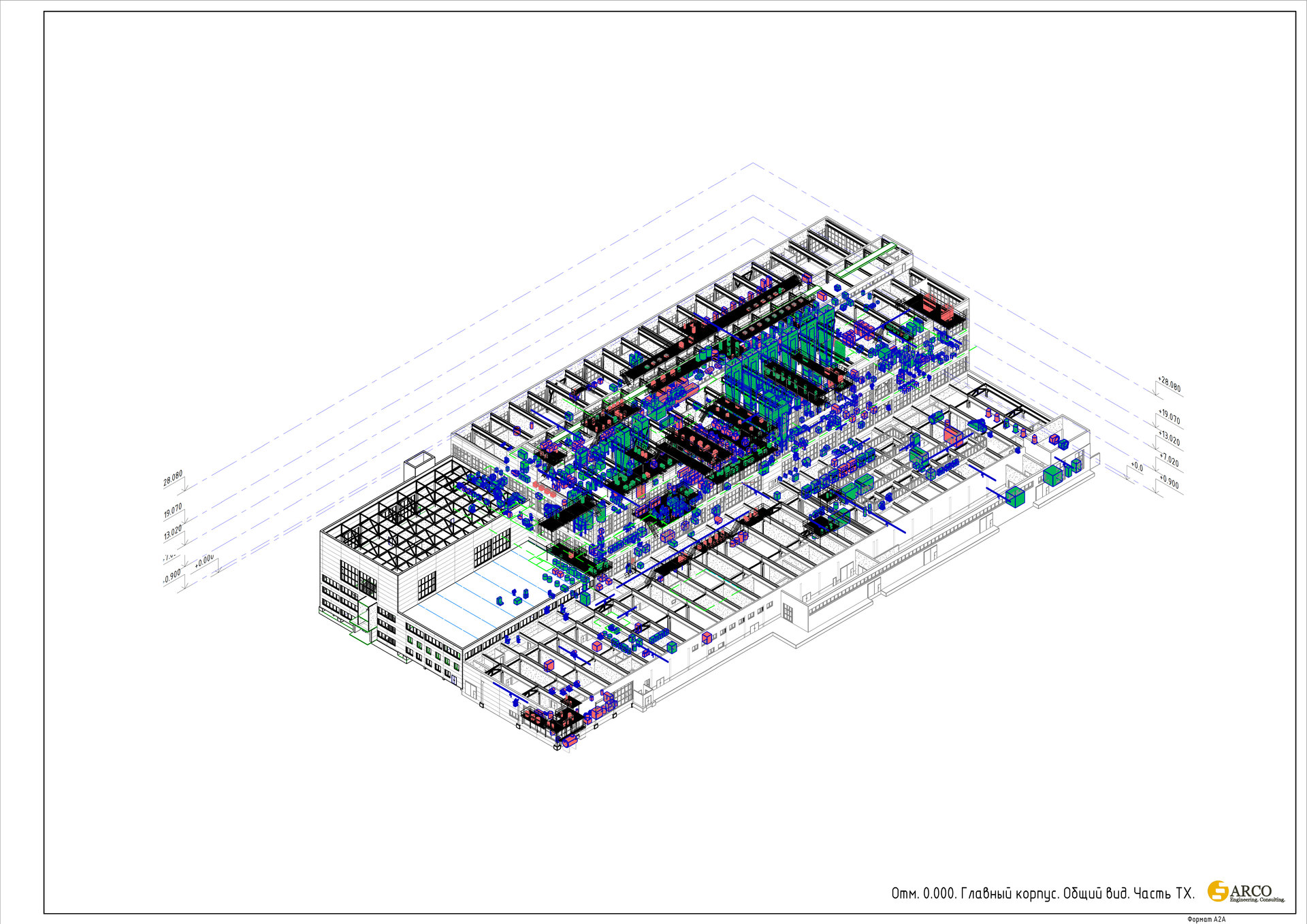

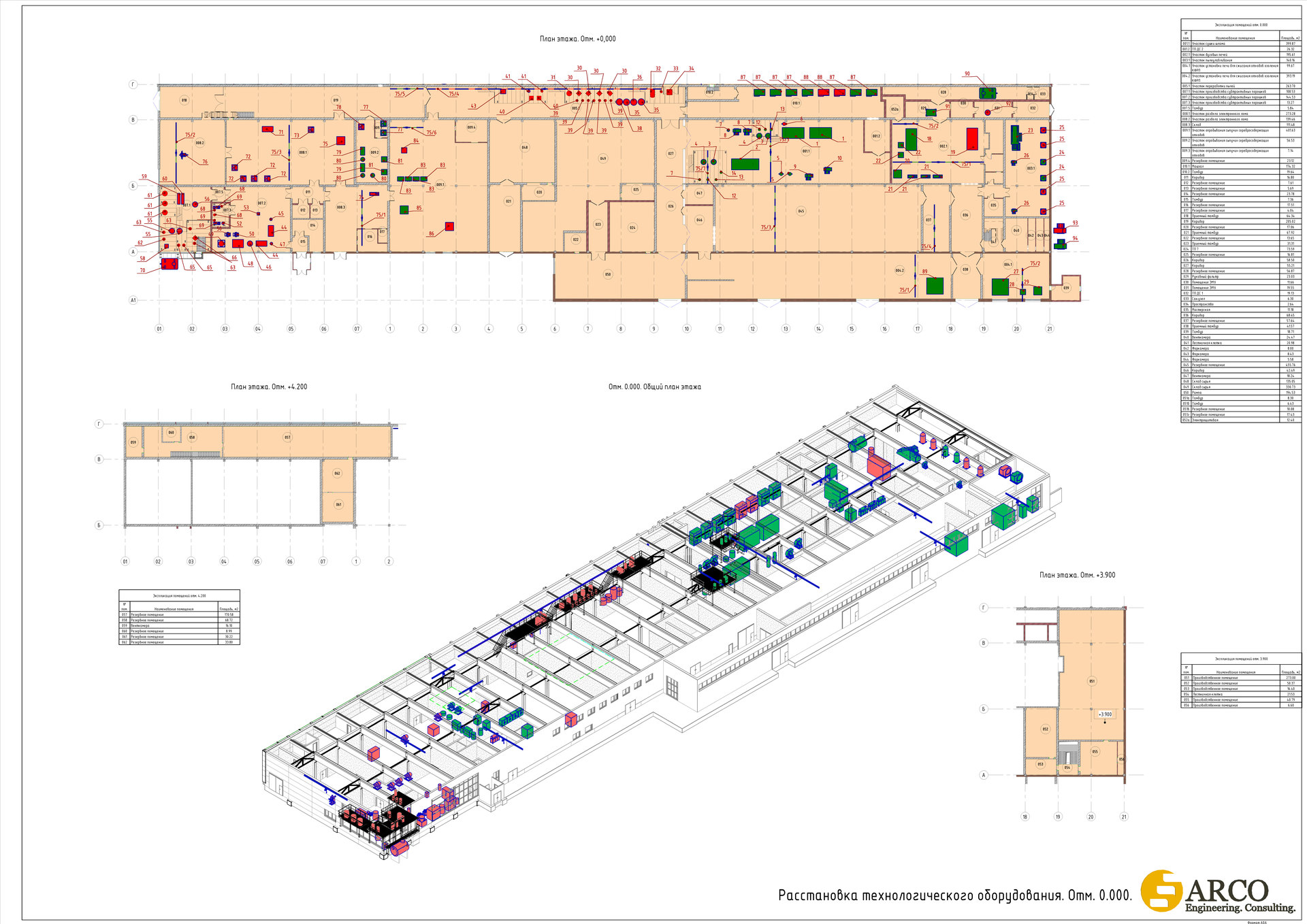

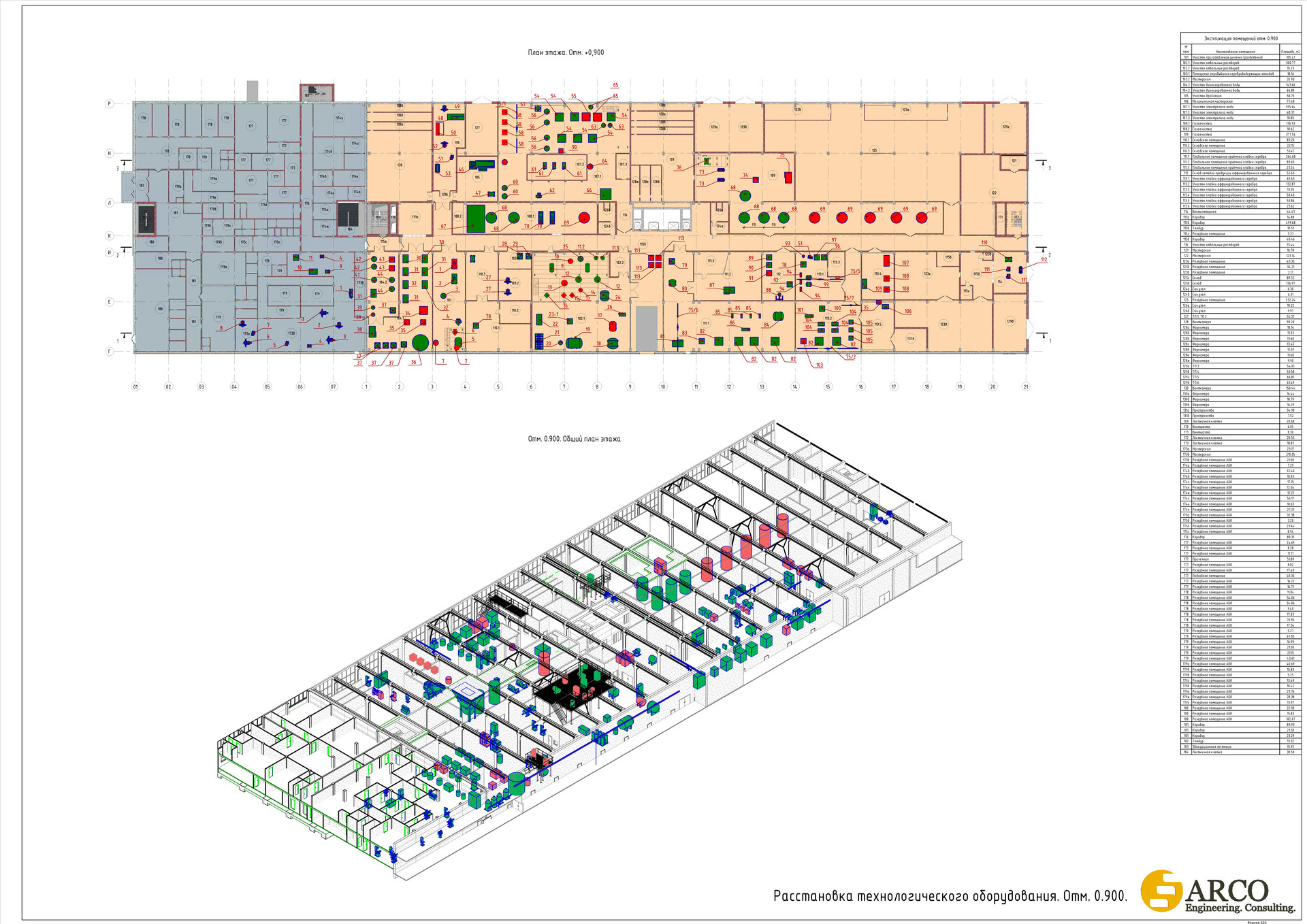

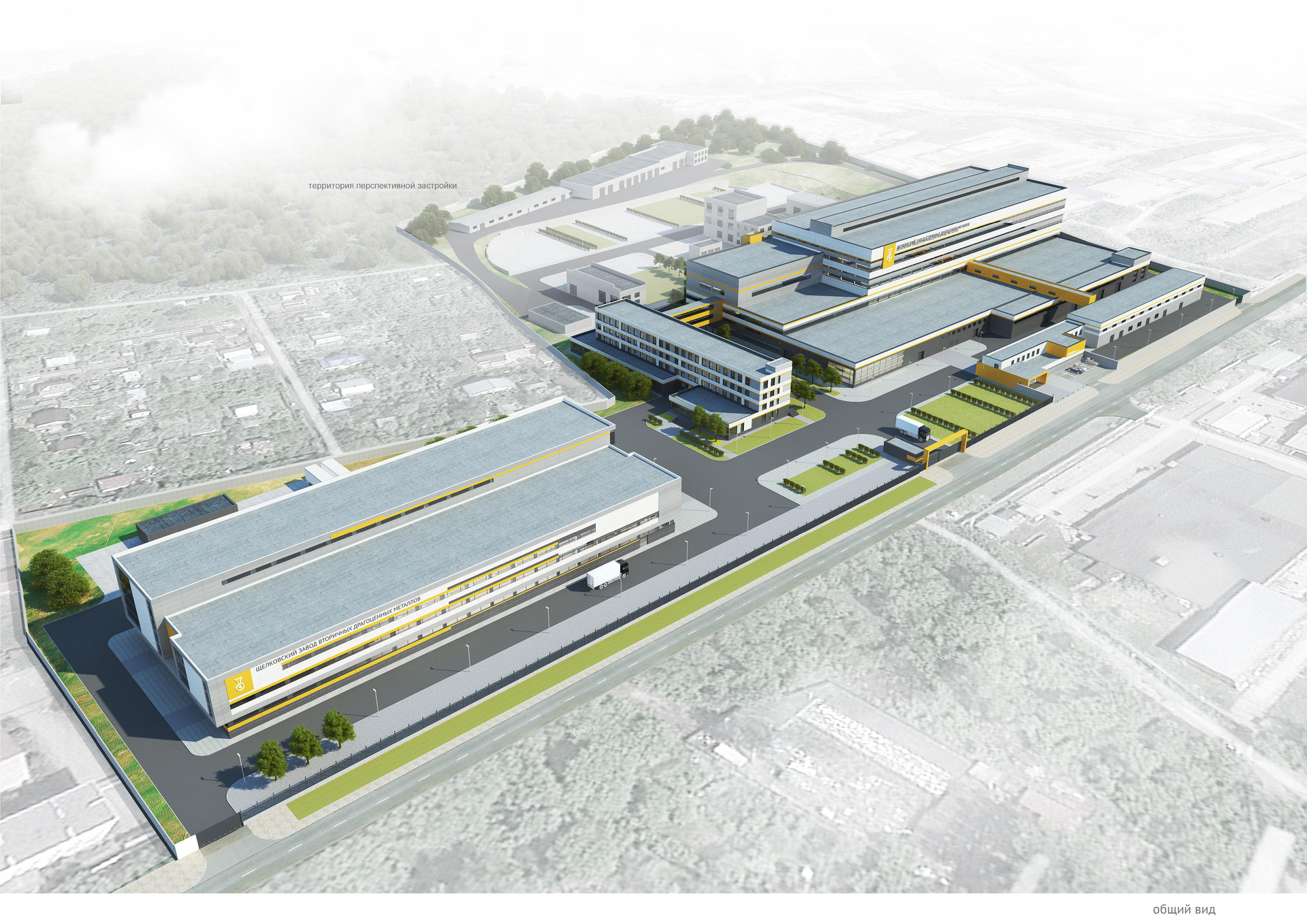

Faced with the problem of the lack of complete, correct and up-to-date design documentation for the surveyed facilities, the specialists of ARCO LLC developed a BIM model, which includes the main production buildings, auxiliary buildings and facilities and network facilities. The zoning of the main technological processes and the layout of technological equipment were carried out (with the inclusion in the BIM model). This BIM model allowed to restore the missing design documentation, reflecting the real state of buildings, structures and equipment.

To expand the use of the capabilities of the BIM model and to identify the information obtained about the objects under study, a 3D tour was developed that made it possible to visualize the current state of buildings, premises of the main production, equipment and engineering systems. 3D tour models of production sites with equipment layout are integrated into the tour.

The BIM model allowed, in addition to visualizing the received information about the objects under study, to determine the actual volumes of the proposed and necessary measures to ensure the operability of engineering systems, buildings and structures. Enlarged estimates of capital costs for the implementation of current and promising activities have been carried out.

A network schedule has been developed for the implementation of the project, reflecting the sequence and laboriousness of work on the implementation of measures for the reconstruction / modernization of on-site facilities.

Based on the actual and estimated data obtained during the study of the industrial site, on the one hand, and the practice of implementing similar projects, on the other, we took the lead and performed comparative (scenario) calculations of time and capital costs for the reconstruction of existing facilities, and creation of a new refining production.

We express our gratitude to the management and specialists of the factory for the prompt response and organization of interaction in fulfilling the tasks set by ARCO LLC.

ARCO LLC, in practice participating in the implementation / management of industrial enterprises modernization projects, assumes a functional role in that part of the project where it is most relevant for the Customer.